Technology

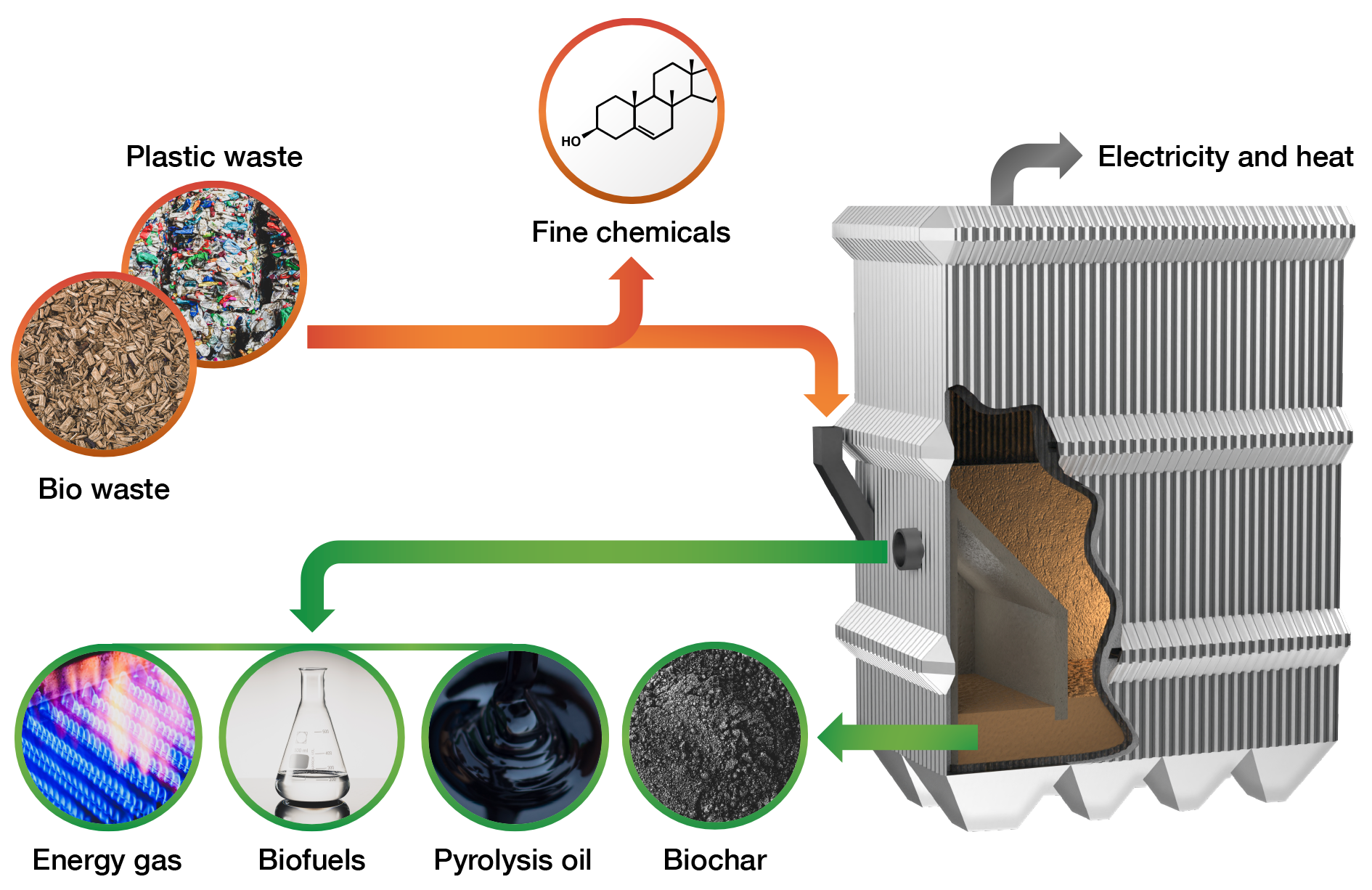

A large combustion plant is a complex process with high demands in terms of availability, efficiency and emissions. BioShare’s strategy to utilize deep integration for cost efficient polygeneration is based on thorough understanding of all aspects of the combustion process. With our patented and patent pending reactors any fluidised bed boiler can be converted to a biorefinery. For large scale applications a thorough assessment of the plant including available biomass, plant configuration, layout and operation parameters is carried out and the resulting technical solution is 100 % tailormade. For low and medium size capacity a cost and space-efficient retrofit of fluidized bed boilers can be accomplished by sectioning of the bubbling bed in the combustion furnace or sand lock.

With our patented concept the bed is divided and the bed material is transferred between the two sections, whereas the gas phases above the bed remain fully isolated. By controlling bed material transport and char residence time in the volatilization stage, the production rate and product composition can be controlled.