Bio waste

Agricultural areas and the world’s forests, covering billions of hectares, represent a tremendous asset. Handled with respect and caution this resource can be managed to contribute to a sustainable society. Lignocellulosic and agricultural residual material currently used in the combined heat and power sector are important sources of energy, but these are also complex polymers with an inherent potential to be used for a broader value creation than merely that accomplished by heat release during combustion. Combining the production of inherent high-value chemicals, high performance industrial energy carriers or biofuels with heat and power production enables the residual streams and waste heat that inevitably follows any conversion process to be captured and utilized.

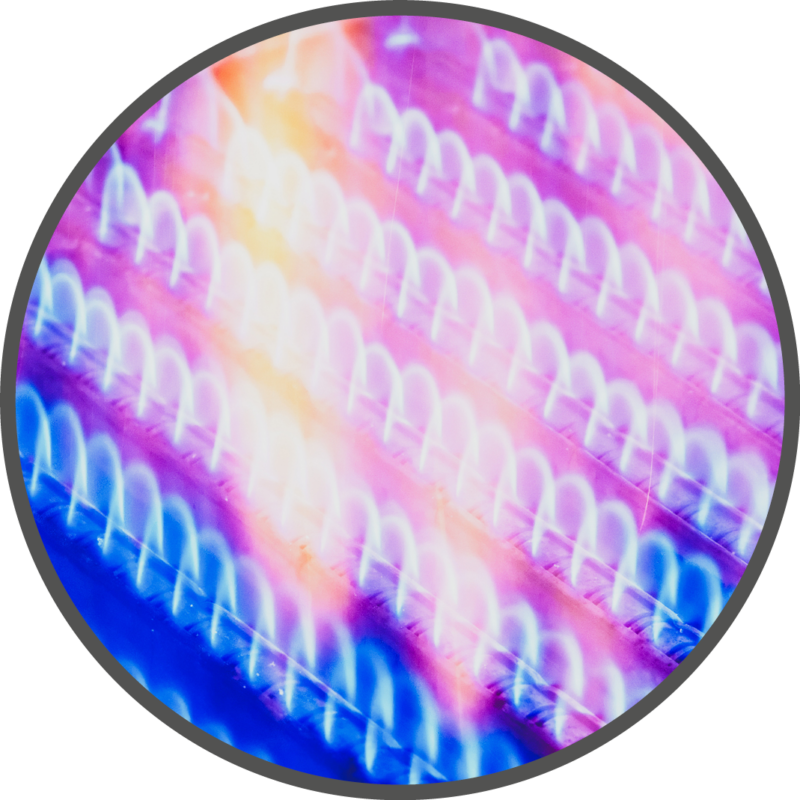

Energy gas

Many industrial sectors uses substantial amount of fossil gases like natural gas and LPG due their need for clean, high temperature energy. Replacing these fossil gases with renewable gas produced by boiler-integrated gasification of woody and agricultural residual streams is a low hanging fruit with moderate technical complexity and high climate impact. Indirect gasification followed by tar removal results in a clean, virtually nitrogen-free gas with high heating value and excellent combustion properties. The gas can be compressed and distributed within the industrial plant, replacing fossil gas in numerous applications. For industries already operating a solid fuel boiler, our integrated gasification concept offers a cost efficient, fast-track solution to fossil independence.

Biofuels

Utilization of biogenic carbon for energy storage should not be considered as an opposite alternative to electrification but as a complement, and availability of renewable liquid or gaseous fuels will be crucial for many transport services for the foreseen future. The thermochemical route to biofuels offers high capacity and wide raw material flexibility. Almost any organic material can be transformed to clean fuels that outperforms conventional fossil fuels in terms of climate footprint and combustion properties. Biofuel production based on gasification offers a robust pathway in which the transformation of biomass to gas phase enables effective cleaning of ash components. BioShare work with deep integration of gasification and subsequent gas conversion processes in combined heat and power plants, focusing on biofuel production in the scale 10-100 MW with superior efficiency.

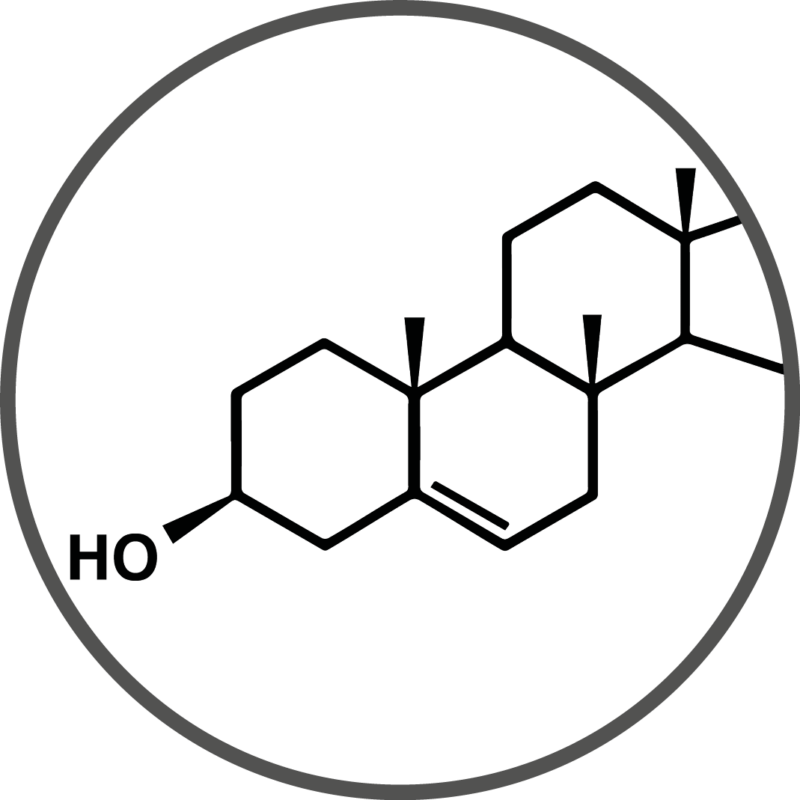

Pyrolysis oil

Pyrolysis of organic material is a process with a wide range of uses. In its simplest form, renewable fuel oil substitutes can be produced, but the technology also attracts great interest for production of raw materials for fuel and plastic production with both biomass and polymers as raw material.

Integrating the pyrolysis production in a boiler plant enables oil quality to be optimized without sacrifying energy efficiency.

Biochar

Extraction of biochar from a thermochemical conversion process is a small- and medium scale alternative for CCS/CCU with low investment cost that enables CHP plants to be CO2-negative

Integrating the biochar process with a boiler plant enables production of a material with high carbon-content and superior system energy efficiency

Fine chemicals

Waste biomass streams contain low concentrations of fine chemicals that can be extracted before the biomass undergoes thermochemical conversion. Extraction of these chemicals represent an option for enhanced value creation at a CHP plant.

Integrating the extraction process in the plants energy system and manage the implication on the boilers in terms of altered load and fuel mix are key for viable production of fine chemicals.